- #Setting presets simplify 3d how to#

- #Setting presets simplify 3d manual#

- #Setting presets simplify 3d software#

- #Setting presets simplify 3d free#

Once you slice your object and set the parameters for the printer, it automatically generates the G code.

#Setting presets simplify 3d free#

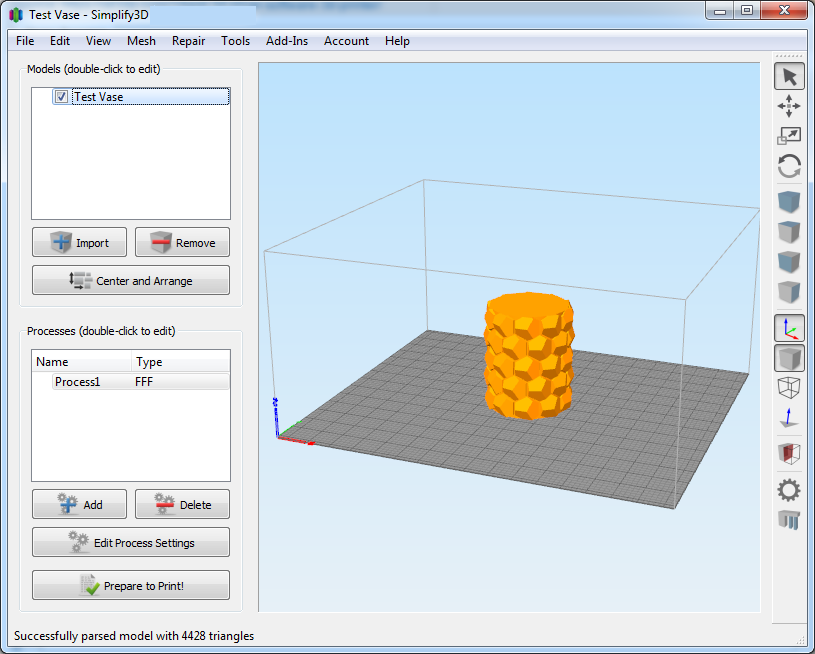

This process has become very simple over time with multiple free programs like Repetier, Cura, and Simplify 3D which is $150 but has some very good features and visualizations. From the STL file the program needs to be sliced and processed into g-code.

#Setting presets simplify 3d software#

These software programs are capable of just taking simple shapes and turning them into very attractive objects to print on our ceramic printer.Īfter you've generated your vessel, it's a simple process with Fusion 360 or any other program to turn it into STL file. There are some simple programs like, Tinkercad, but our favorite is Fusion 360 which is free for students and small businesses. In order to create an object you must first develop a shape.

#Setting presets simplify 3d how to#

Please watch our Extruder Tube Changing video for a full tutorial on how to easily change your tubes.īasic object creation and slicing tutorial: Moving parts, such as the acme screw, need to be kept free of all debris. This is the hardest loading method.Ĭhanging out an empty tube on an extruder for a full one has many steps involved. As you force clay you can tap the tube to move the clay further down as you continue to load the tube. If the consistency of the clay is correct, you can eliminate the air at the same time.

This is done with a trowel or a spatula on a flat table. That's it, this is your best method to load your tubes without a pug mill. Tap the tube and nozzle on soft piece of carpet so not to damage it. Put the nozzle on the tube with tape over the end and gently tap the long piece of clay into the tube. Now take out the clay that has the proper moisture content, roll it into a cylinder a little bit smaller then the diameter of inside of the tube. Wait until the water has penetrated the clay, usually one to two days.

Now roll up the bag again and make it airtight. The simple answer is add 15 ounces of water to standard 25 pound bag of clay.Ĭut the square bag of clay into 4 long pieces and put microfiber towel in between the clay pieces before adding water. This happens because the auger has no traction against the side of the pug mill as the clay mixture becomes too loose. It also depends on the pug mill and its ability to forcefully push the clay. If too much water is added to the clay the pug mill can actually not function sufficiently enough to load the tubes. This can be accomplished by running the clay through the pug mill and adding small quantity of water. The consistency of the clay should be similar to a standard throwing clay, but wetter. Although a single auger is adequate, the consistency of the clay is more critical when it comes to loading the tubes. It's necessary to machine a small transitional flange from the nozzle of the pug mill to hold the polycarbonate tube in place.įor best results you should use a de-airing pug mill and a double auger will give you better performance than a single auger. The easiest way by far is with the use of a pug mill. There are several ways to load the cylinders. We have yet to make up our own clay preparation and this is another way to go. There's so much to say and so much experimenting to be done in our 3D ceramic studio. This also depends on your environment temperature and humidity. Especially on larger vessels where the nozzle comes around to the overlap point after period of time the moisture doesn't seem to be there.

Interlayer adhesion seems to be a problem as the moisture dissipates too quickly on a large print for the layers to adhere. The interlayer adhesion is a little bit less than the stoneware also but this doesn't seem to be a problem as long as you do not let the moisture come out of the clay too fast after printing.Īxner Mary's Porcelain Clay is the only porcelain that we have experimented with. The Vince's Low White Clay earthenware performs well also although it does not extrude as easily as the stoneware. We do add some water to the stoneware which seems to help with interlayer adhesion and ease of extrusion. It has the best interlayer adhesion and is quite easily extruded in both of our extruders. WC-902 Axner Mary's Porcelain Clay - porcelainĮM‑700 Vince's Low White Clay - earthenwareĪfter all the testing we seem to prefer the Maccabees cone 5 stoneware. These are our favorite clay bodies which are readily available here in the USA from any pottery supply or ceramic craft studio. Then the tubes can be loaded directly from the pug mill. Use pug mill and add small amounts of water while cycling the clay through the pug mill several times to get the right consistency.

#Setting presets simplify 3d manual#

Manual wedging with adding extra water until the consistency is right.ģ. The moisture from the cloth will penetrate into the clay in about a day or so.Ģ. Cut purchased clay into smaller sections, put in micro fiber towel or felt in the plastic bag add 10-15 oz of water, close the bag.

0 kommentar(er)

0 kommentar(er)